In cleanroom environments, flooring is a critical element for contamination control, air cleanliness, product quality, and personnel safety. High-quality cleanroom flooring enhances cleanability, durability, and long-term compliance with industry standards. For pharmaceuticals, semiconductors, biotechnology, and life-science labs, selecting the right flooring for clean room helps reduce risks from particles, microbes, and static electricity while ensuring compliance with GMP and ISO 14644.

Rubber flooring is widely used in high-tech manufacturing and laboratory environments due to its exceptional durability, impact resistance, and superior ESD control. Brands such as Nora use 1 m² solid sheets installed with cold welding to create seamless surfaces that prevent particle accumulation. Rubber flooring is ideal for areas with heavy equipment movement and for ESD-sensitive environments such as electronics or medical device manufacturing. In pharmaceutical clean room flooring projects, rubber floors are often chosen for their longevity, ease of maintenance, and high cleaning efficiency.

This is a cost-effective solution for small cleanrooms or low-load areas. Vinyl flooring can extend up walls to form coved edges, eliminating cleaning dead corners. However, due to its lower resistance to heavy traffic and equipment loads, it is best suited for light-to-medium-duty cleanroom applications.

Epoxy flooring provides an attractive, low-porosity, and highly sealed surface, ideal for cleanrooms with well-prepared concrete substrates. With thicknesses ranging from 10–25 mils, epoxy can smooth out minor imperfections and offers excellent chemical resistance. While epoxy may be slightly less stain-resistant and wear-resistant than urethane systems, it remains a strong, cost-efficient cleanroom flooring option.

The standout advantage of MMA flooring is its ultra-fast cure time—typically less than one hour—and its ability to be installed even in low-temperature environments down to –20°C. MMA systems are highly durable, impact-resistant, antimicrobial, and low-glare, making them ideal for pharmaceutical facilities, cold-chain laboratories, and biosafety environments where downtime must be minimized.

Urethane flooring offers superior wear resistance, heavy-load tolerance, and outstanding resistance to a wide range of chemicals, including acids, alkalis, fuels, and hydraulic oils. It is well-suited for environments requiring frequent cleaning, heavy equipment movement, or exposure to corrosive substances. Anti-slip additives can be incorporated to enhance operator safety.

VCT is commonly used in Class 7 & 8 cleanrooms in the electronics sector due to its low upfront cost and availability in ESD-safe versions. However, because it contains many seams and requires frequent maintenance, it is not recommended for pharmaceutical, food, or medical cleanroom environments.

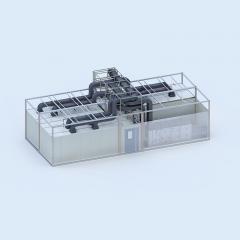

Raised flooring is common in semiconductor and high-grade cleanrooms where top-down laminar airflow is required. It improves air circulation efficiency and supports easy cable and pipe routing. Available in solid, perforated, and grating panels, raised floors can be selected based on airflow requirements, pressure differentials, and ESD needs. They also offer flexibility for equipment upgrade or layout adjustments.

To achieve long-term operational reliability and regulatory compliance, organizations should consider the following factors when selecting cleanroom flooring:

By evaluating these criteria, organizations can choose a flooring for clean room solution that maximizes cleanliness, safety, durability, and cost-efficiency—all while maintaining full compliance with industry and regulatory standards.